Best Nesting Software for Laser Cutting [2023]

Nesting is a process that arranges the shapes from a design so that it takes up less space and reduces material wastage.

It can be done manually by moving and orienting each shape or automatically using complex algorithms used by different software.

This article talks about some of the best nesting software used for laser cutting applications.

In the end, I will also give you an overview of nesting and its advantages through examples.

MellowPine is reader-supported. When you buy through links on my site, I may earn an affiliate commission at no extra cost to you.

Mục lục bài viết

Best Nesting Software

SoftwareCostNest&CutPaid and freeLantek Expert CutPaidDeepnestFreeeCutPaidSigmaNESTPaidProNestPaidSVGnestFreeMyNestingPaid

Best nesting software for laser cutting

Nesting is the process of optimizing the design layout to ensure maximum utilization of workpiece material and reduce wastage.

These software programs are generally useful for applications like laser cutting sheet metal, laser cutting leather, etc. where the cost of raw material is significantly high.

A good nesting software not only reduces wastage but also improves the overall manufacturing cost of the project.

Nest&Cut – Best Web-based Nesting Software

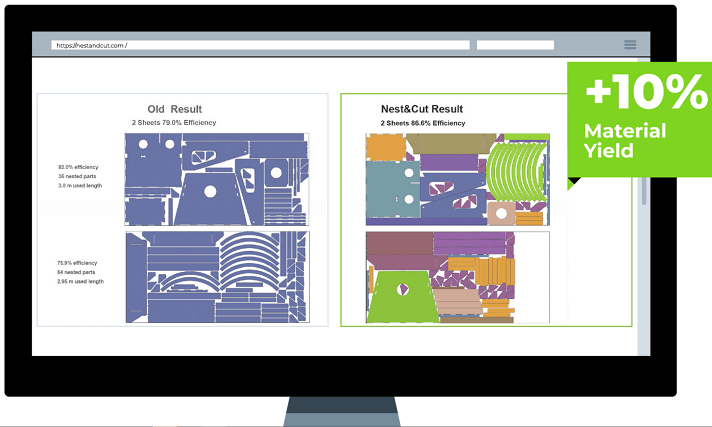

Increased nesting efficiency with the re-nesting feature on Nest&Cut (Source: Nest&Cut)

Increased nesting efficiency with the re-nesting feature on Nest&Cut (Source: Nest&Cut)

ParameterNest&CutCADYes (basic)CAMYesControlNoFile FormatsImport – DXF, DWG

Export – DXF, NC code

Comming Soon – Amada, Hypertherm, CypCut, G-codeOSOS independent

(Web-based)Internet required?YesPaid/FreePaid (Full access)

Free (with limitations)

Quick summary of Nest&Cut nesting software

Nest&Cut is a powerful web-based nesting software. It runs on most browsers and does not need a high-performance computer to run the program as all the processing is happening on the server-side.

Since it uses server-side processing, you will need internet access to work using this software.

Though it is paid software, you can use it for free, but you will be limited to exporting files in DXF or DWG file formats.

On the paid version of the software, you can export your design in G-code file format which is accepted by most laser control software.

Re-nesting, order generation, multiformat nesting, inside-part nesting, parts cleaning, etc., are some notable features tailored to its nesting ability.

Lantek Expert Cut – Best for Industrial Applications

Lantek Expert Cut (Source: Lantek)

Lantek Expert Cut (Source: Lantek)

ParameterLantek Expert CutCADYesCAMYesControlNoFile FormatsDXF, DWG, IGES, DSTV, JPEG, BMP, TIF, GIF, PCX, etc.OSWindowsInternetOccasionallyPaid/FreePaid

Quick summary of Lantek Expert Cut nesting software

Lantek Expert Cut is a paid industrial-level CAD/CAM compatible nesting software.

If you are a hobbyist, you would not need this software. Its application mainly focuses on laser-cutting metal sheets that are done mainly in industrial setups.

Nesting operation in Lateck Expert Cut has a combination of automatic and manual tools, making the process much more flexible.

It stores the remnant cut parts in its warehouse library and prioritizes them using a completely new sheet.

Once the nesting process is done, you can export the files in DXF, DWG, IGES, DSTV, and more.

Lantek Expert Cut runs on Windows OS and requires a minimum of 1GB RAM.

It may require internet access occasionally to perform its updates and authentication activities.

Deepnest – Best Free Nesting Software for Hobbyists

Deepnest nesting software (Source: Deepnest)

Deepnest nesting software (Source: Deepnest)

ParameterDeepnestCADNoCAMNoControlNoFile FormatsImport – DXF, SVG, Corel CDR

Export – SXF, SVGOSWindows, Mac, and LinuxInternetNo Paid/FreeFree

Quick summary of Deepnest nesting software

Deepnest is an open-source nesting software and can be installed on systems running Windows, Mac, and Linux OS.

It has a simple workflow, Import the file> select the sheet > start nest.

You can import DXF, SVG, and Corel CDR file formats into the software and export files in DXF or SVG formats.

Deepnest can also nest bitmap images for laser engraving applications.

Its automatic line merging feature is an absolute time-saver as it can merge adjacent lines so that the laser cutter only needs to cut the path once.

eCut nesting plug-in on CorelDRAW (Source: Trotec Canada – YouTube)

eCut nesting plug-in on CorelDRAW (Source: Trotec Canada – YouTube)

ParametereCutCADNoCAMNoControlNoFile FormatsAdobe Illustrator and CorelDRAW filesOSWindowsInternetOnce

(for activation)Paid/FreePaid

Quick summary of eCut nesting software

eCut (nesting pack) is a plug-in software that enables you to do nesting operations on CorelDRAW and Adobe Illustrator software.

It only supports Windows OS, and its hardware requirements are the same as the installed CorelDRAW or Adobe Illustrator software.

eCut is a paid software. You can also try this software in “test mode” for four days. During this period, you can use all functions of the software.

For activating the software, you need internet access as it generates the software unlock code by crosschecking the activation key and system ID.

SigmaNEST software interface (SigmaTEK Systems, LLC – YouTube)

SigmaNEST software interface (SigmaTEK Systems, LLC – YouTube)

ParameterSigmaNESTCADYesCAMYesControlNoFile FormatsDXF, DWG, IGES, DSTVOSWindowsInternetYesPaid/FreePaid

Quick summary of SigmaNEST software

SigmaNEST is a CAD/CAM-compatible nesting solution for industrial-level applications.

The software has five versions available: AutoNEST, TrueShape, Techno, Maximizer, and PowerPack.

All versions can import and use DXF, DWG, IGES, and DSTV files. They can also do 2D CAM operations.

The software is customizable and can be installed on systems running on 64-bit Windows OS (version 8.1 and above).

SigmaNEST requires a minimum of 4GB RAM and needs an active internet connection for its operation.

It offers features like rectangular nesting, part-to-part nesting, shear nesting, continuous nesting, and more.

ProNest software interface (Source: Hypertherm)

ProNest software interface (Source: Hypertherm)

ParameterProNestCADYesCAMYesControlNoFile FormatsImport – Most CAD files, including PDF

Export – NC code, DXFOSWindowsInternetOccasionallyPaid/FreePaid

Quick summary of ProNest software

ProNest is a CAD/CAM-compatible laser nesting software developed by Hypertherm.

It is an industrial-level software available in two versions, ProNest and ProNest LT. ProNest is for large-scale industrial applications, and ProNest LT is for light industrial cutting applications.

The nesting features include manual nesting, intelligent automatic nesting, plate inventory, work order processing, management reports, and more.

ProNest can be installed on any system running on 64-bit Windows OS (8/8.1/10). However, you will need a minimum of 8GB RAM for its optimum operation.

With the purchase, you will get unlimited technical support and training. Also, you do not have to pay for future software updates.

SVGnest processing interface (Source: Ponoko)

SVGnest processing interface (Source: Ponoko)

ParameterSVGnestCADNoCAMNoControlNoFile FormatSVGOSOS independent

(Web-based)InternetYesPaid/FreeFree

Quick summary of SVGnest software

SVGnest is one of the oldest successful nesting software experiments from the developer of Deepnest.

It is an open-source web-based software that anyone can use for free. However, it requires an active internet for the software to load and process the operations.

Since it is a web-based software, it is OS independent and can run on most devices that have a web browser.

SVGnest uses pixel as the unit for measurement which is a standard unit for most SVG files.

MyNesting software interface (Source: MyNesting)

MyNesting software interface (Source: MyNesting)

ParameterMyNestingCADNoCAMNoControlNoFile FormatsDXF, DWGOSWindowsInternetYesPaid/FreePaid

Quick summary of MyNesting software

MyNesting is a paid nesting software that can be installed on systems running Windows OS.

They offer a unique credit-based nesting option in which you only have to pay when you want to download the nested file.

The software also has a period-based unlimited nesting subscription plan but is priced slightly high.

MyNesting can import most CAD files. Once it imports, it runs the nesting in an automatic mode and has most features like inventory, work order, etc., which a standard nesting software will be having.

Nesting and its Advantages in Laser Cutting

When you have some designs to be cut out from a sheet of material, it will be helpful to place/house those shapes within each other or nearer to their cut paths.

It is what exactly happens in a nesting operation, and it is almost like building a puzzle with given shapes.

The nesting algorithm used by nesting programs continuously runs calculations to find the best-fit arrangement for the parts to fill in the worksheet effectively.

Nesting operations can be done manually or automatically. If you are doing it manually, it will be best to do it right there in the designing stage. If your design/artwork has many complex shapes, the best option would be automatic nesting using dedicated software.

Advantage

You can minimize the cost per cut in a laser cutter by effectively using the worksheet material by nesting the cut-out designs.

It increases the capacity of a worksheet as it tightly packs everything, allowing you to place more designs within the worksheet.

Also, when multiple cut paths are aligned together, you can cut out everything at once. It saves time.

Nesting Example

Manual Nesting

An example of manual nesting

An example of manual nesting

In the above-given example, the “regular design” needed a worksheet size of 34.6″ x 22.6″. However, the “nested design” only needs a worksheet size of 22.7″ x 20.3″ after the manual nesting operation.

So here, the nesting operation helps save around 320 square inches of material.

Manual nesting can be done on most CAD software, and generally, it requires the use of rotation and move tools.

Automatic Nesting

The following images show a sample workflow from SVGnest, an automatic nesting software.

Step 1: An SVG image imported to the software, which has all the designs needed to be cut out from a sheet of material and a sample of worksheet with proper dimensions.

Step 1: An SVG image imported to the software, which has all the designs needed to be cut out from a sheet of material and a sample of worksheet with proper dimensions. Step 2: Select the worksheet (highlighted in black) for housing all other designs within it using the nesting function.

Step 2: Select the worksheet (highlighted in black) for housing all other designs within it using the nesting function. Step 3: Press the “Start Nest” button. This will start the nesting operation.

Step 3: Press the “Start Nest” button. This will start the nesting operation. Step 4: Designs tightly packed inside the workpiece after the automatic nesting operation.

Step 4: Designs tightly packed inside the workpiece after the automatic nesting operation.

Check out the article “Best Laser Engraver/Cutter Software: Free & Paid!” to know about different CAD, CAM, and control software that can be used for laser cutting applications.

Frequently Asked Questions

What is CAD-CAM Nesting?

CAD-CAM nesting is the process of doing nesting operation during CAD/CAM operation. CAD nesting optimizes the design in the CAD stage itself, but in CAM nesting, the designs are optimized while generating the toolpath. The nesting can be manual or automatic.

What is the Major Challenge in Nesting While Laser Cutting?

The major challenge in nesting while laser cutting is optimizing the nested design as per the worksheet material. For example, you can place designs closer in cardboard workpieces and get a clean cut with a laser. However, when the same is done on a plastic sheet, melted plastic will give uneven burned cuts along a cut path. Therefore, each design must be placed at a safe distance from the other in such cases.

Can I use CO2 Laser Nests for Fiber Laser Fabrication?

Yes, you can use CO2 laser nests for fiber laser fabrication. However, remember, fiber lasers generally process at a much higher speed than CO2 lasers. Therefore, it will be better to take advantage of this speed if you have a dedicated design optimized for fiber lasers.