What Is a Programmable Logic Controller (PLC)?

In today’s society, we rely on automated machinery to perform many of our most critical industrial processes, from generating electricity to weaving fabric. Automation technology has allowed us to scale new heights of production and innovation. But our current level of automation wouldn’t be possible without a critical invention called the programmable logic controller (PLC).

What is a programmable logic controller, and how do these controllers help us run the many processes that our modern world requires? What are the pros and cons of PLCs? If you’re asking these questions, this edition of our TechTalk blog is for you.

Our beginner’s guide to PLCs will introduce you to the basics of PLCs, talk about why these controllers are so important and provide a quick primer on how they work. We’ll also talk about some of Polycase’s best electrical enclosures for PLCs that will protect your most critical control systems.

Mục lục bài viết

What Is a Programmable Logic Controller?

A programmable logic controller is a type of tiny computer that can receive data through its inputs and send operating instructions through its outputs. Fundamentally, a PLC’s job is to control a system’s functions using the internal logic programmed into it. Businesses around the world use PLCs to automate their most important processes.

A PLC takes in inputs, whether from automated data capture points or from human input points such as switches or buttons. Based on its programming, the PLC then decides whether or not to change the output. A PLC’s outputs can control a huge variety of equipment, including motors, solenoid valves, lights, switchgear, safety shut-offs and many others.

The physical location of PLCs can vary widely from one system to another. Usually, however, PLCs are located in the general vicinity of the systems they operate, and they’re typically protected by a surface mount electrical box. Skip to the end if you’re interested in seeing the electrical junction boxes that help protect PLCs.

PLCs largely replaced the manual relay-based control systems that were common in older industrial facilities. Relay systems are complex and prone to failure and, in the 1960s, the inventor Richard Morley introduced the first PLCs as an alternative. Manufacturers quickly realized the potential of PLCs and began integrating them into their work processes.

Today, PLCs are still a fundamental element of many industrial control systems. In fact, they’re still the most used industrial control technology worldwide. The ability to work with PLCs is a required skill for many different professions, from the engineers designing the system to the electrical technicians maintaining it.

Advantages of Using PLCs

PLCs have been a standard element of industrial machinery design for many decades. What advantages do PLCs offer that make them such a popular choice?

-

PLCs are fairly intuitive to program. Their programming languages are simple in comparison to other industrial control systems, which makes PLCs great for businesses that want to minimize complexity and costs.

-

PLCs are a mature technology with years of testing and analysis backing them up. It’s easy to

find robust research about many different PLC types

and comprehensive tutorials for programming and integrating them.

-

PLCs are available at a wide range of price points, including many extremely affordable basic models that small businesses and startups often use.

-

PLCs are extremely versatile, and most PLC models are suitable for controlling a wide variety of processes and systems.

-

PLCs are completely solid-state devices, which means they have no moving parts. That makes them exceptionally reliable and more able to survive the challenging conditions present in many industrial facilities.

-

PLCs have relatively few components, which makes them

easier to troubleshoot

and helps reduce maintenance downtime.

-

PLCs are efficient and don’t consume very much electrical power. This helps conserve energy and may simplify wiring considerations.

Drawbacks of Using PLCs

No technology is perfect for every scenario, and there are some applications for which PLCs aren’t the best choice. Let’s look at some of the most significant potential drawbacks of using PLCs.

-

PLCs have less capacity to handle extremely complex data or large numbers of processes that involve

analog rather than discrete inputs

. As manufacturing facilities become more integrated and involved, increasing numbers of them may shift toward a

distributed control system

or another alternative industrial control method.

-

PLCs from different manufacturers often use proprietary programming software. This makes PLC programming interfaces less interoperable than they might be, especially considering that their programming languages share common standards (see below).

-

PLCs, like many other types of electronic equipment, are vulnerable to electromagnetic interference (EMI). They can also experience other kinds of common electronics malfunctions such as corrupted memory and communication failures.

How a Programmable Logic Controller Works

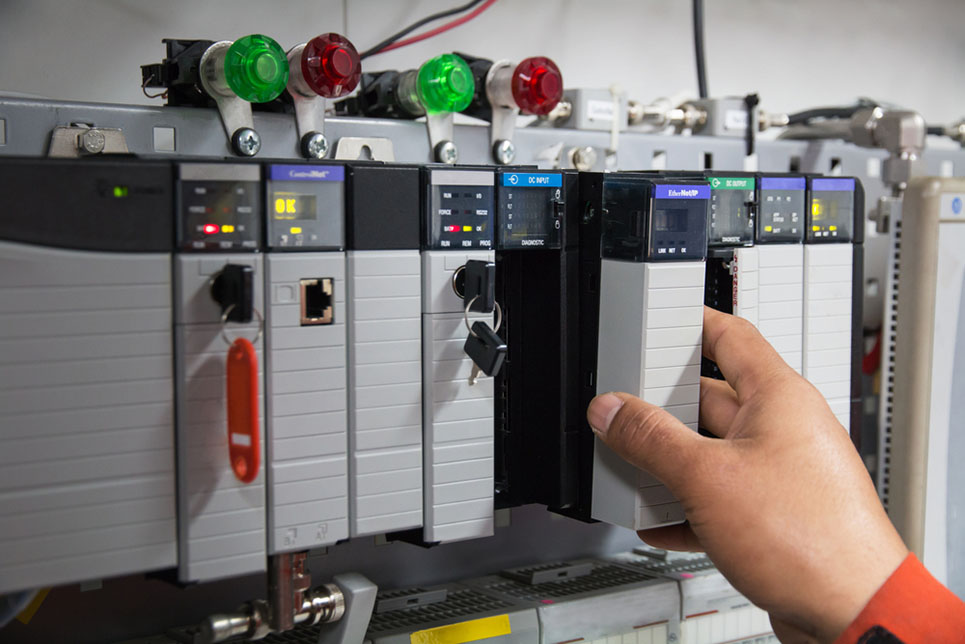

Now let’s take a look at what’s going on inside a programmable logic controller. Remember that a PLC is an input-output system, which means that each unit both accepts inputs and controls outputs. Between inputs and outputs is the third element of the system: logic programming, which happens in the CPU and controls the relationship between the inputs and outputs.

Here’s how each element works:

-

Input Monitoring: The PLC monitors relevant data inputs and sends the data to the CPU. Some PLCs only use data inputs with discrete (on/off) inputs, but PLCs with analog capabilities can accept analog inputs for continuous variables. Inputs may come from IoT devices, robots, safety sensors,

human-machine interfaces

, or almost any other type of data entry point.

-

Logic Programming: Every PLC is built with a microprocessor CPU, either 16-bit or 32-bit. Engineers and technicians program the PLC CPU to recognize certain conditions and values and to make changes in the outputs based on its programmed rules. The CPU is constantly checking the state of variables and making decisions based on programmed conditions. This simple premise allows a wide variety of designs and functions.

-

Output Control: Based on the programmed logic, the PLC controls various switches, motor starters, relays, and other devices connected to its outputs. This allows the PLCs to take control of mechanical processes such as the operation of a machine. Engineers can also link multiple system parts by programming PLCs to send their output signal to another PLC in a chain.

Compact PLC units generally include the CPU, inputs, and outputs in the same unit. In the rack-mount modular PLC systems that many industrial facilities use, the PLC’s inputs and outputs are located together in the I/O module, while the logic operations happen in a separate CPU module. I/O modules may be located close to the CPU, but they can also be quite distant — sometimes even in different buildings.

Choosing a PLC

Many factors will influence your choice when it comes to specifying a PLC model for your application. Some key considerations include:

-

Electrical Capacity: PLCs have different voltage requirements for their power supplies, so check to ensure that your selection is compatible with your electrical system.

-

Processing Speed: Check a PLC model’s CPU speed to determine whether it meets your application’s needs.

-

Compatibility: Ensure that your PLC model is compatible with any new or existing system hardware, whether that’s power supplies or

DIN rails

.

-

Temperature Tolerance: Most PLCs are designed for safe operation within the range of

0 to 60°C

. However, some specialized PLC models can operate at extreme temperatures, which is important for facilities with unusually hot or cold manufacturing conditions.

-

Memory:

A PLC needs sufficient ROM and RAM

to execute the processes it’s intended to automate. The controller uses ROM to store its operating system and instructions and RAM to execute its functions.

-

Connectivity: Make sure your PLC has enough input and output ports, and make sure it’s able to connect to the type of peripherals that your system requires.

-

Analog I/O: Although PLCs are primarily used for discrete functions, some models also have analog inputs and outputs that can control processes with continuous variables.

Programming a PLC

Most PLCs can be programmed using a standard computer and PLC programming software. The International Electrical Code’s IEC 61131-3 standard defines five languages for PLC programming. Three of those languages use graphical interfaces for programming, while the two others use text interfaces.

Ladder logic has traditionally been the most commonly used programming language for PLCs. It’s one of the most intuitive languages available because it uses a graphic interface that’s designed to resemble electrical diagrams, even using many of the same symbols for contacts and relays. Ladder logic uses a series of “rungs” to represent a controller’s I/O channels, each of which can be programmed with conditions and rules.

However, other PLC programming languages offer more sophisticated tools. For example, structured text (ST) allows programmers to quickly create complex, scalable programs using text commands. For the most complex tasks, there’s a sequential function chart (SFC), which allows programmers to connect multiple systems and subroutines in other programming languages.

As we mentioned earlier, it’s common for PLCs to use proprietary software. However, although it might feel unfamiliar to navigate a new PLC programming application, remember that each still operates under the basic principles of IEC 61131-3.

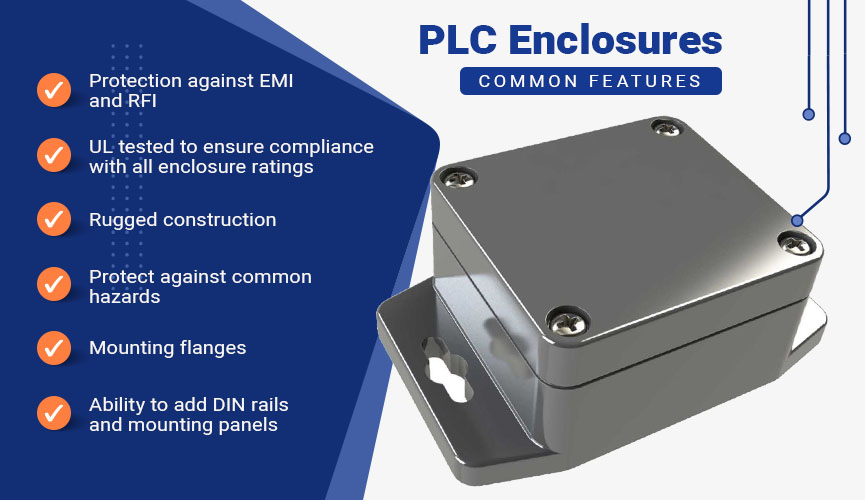

Enclosures for Protecting Your PLCs

We’ve talked about how tough PLCs are, but that doesn’t mean they don’t need protection. On the contrary, a busy industrial workplace poses many hazards to critical equipment like PLCs. Managers need to ensure that their facilities are using the appropriate electrical enclosures to protect control systems.

Common features that designers look for when specifying an enclosure for a PLC include:

Polycase is proud to be a trusted partner and source for PLC enclosures to many manufacturers. We offer our customers a full range of electrical enclosures that are ideal for housing PLCs.

These are some of the models that our customers most commonly use for PLC enclosures:

-

Polycase WA Series: These indoor

ABS enclosures

are among our most affordable options, but their NEMA 4X rating means they don’t sacrifice durability. They’re an ideal choice for workhorse PLC enclosures for applications that won’t see extreme conditions but demand some extra protection from water and debris.

-

Polycase ZH Series

: Convenience meets extreme durability in the ZH Series hinged polycarbonate enclosures, with NEMA 6P and IP68 rated protection to keep your PLCs safe and dry. They are available with gray or transparent covers.

-

Polycase AN Series

: The AN Series is ideal for any application in which PLCs need both NEMA 6P protection and natural EMI/RFI resistance. These enclosures’ diecast aluminum construction is robust enough for even the toughest applications.

-

Polycase HD Series: These sleek and cost-effective

NEMA 6P polycarbonate enclosures

are among our top options for rugged PLC housings. Molded PCB mounting bosses and wall mount flanges make it a plug-and-play solution for many different PLC configurations.

-

Polycase SA Series: When it comes to security and image, SA Series stainless steel

NEMA 4X enclosures

are top performers. It’s all thanks to their 304 stainless construction, hinged door with waterproof gasket and natural EMI/RFI shielding making it the perfect

lockable enclosure

that keeps your PLCs free of interference.

Whether you need an enclosure for your PLC rack or something else entirely, Polycase is here to help. Our experts will be happy to assist you with choosing the best enclosure for your needs, customizing an enclosure, placing a special order or anything else you need. Get started by calling us at 1-800-248-1233 or contact us online today.

Image Credits

1st footage/Shutterstock.com

rozdemir/Shutterstock.com

Xmentoys/Shutterstock.com

Surasak_Photo/Shutterstock.com

Vector Art Gallery/Shutterstock.com

cyberexa/Shutterstock.com